- Home

- About Us

- Machines

- Cups & Containers

- Support

- Contact Us

- Customer Portal

Service Bulletin: SB 177.1

Subject: Mandrel Assembly Replacement

Recommendations:

Because of a stack-up of part tolerances, the mandrel stem face may not fit flush with the leading edge of the nose cone. This condition results in an inability to achieve the proper cup bottom depth when the gap between the bottom finish station and the mandrel stems is set to specification. To eliminate this variation, all future mandrel assemblies will have a grind spacer (p/n 222-820 [Figure 1]) that will need to be individually fit to each cup machine.

PROCEDURE:

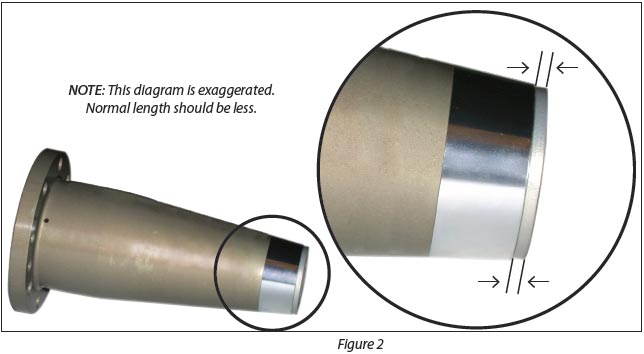

Rotate the machine until a mandrel assembly that has an new grind spacer is between the bottom incurl station and the bottom finish station. In this position the mandrel stem will be fully extended. Measure the distance from the face of the mandrel stem to the leading edge of the nose cone (Figure 2 [on back page]). This measurement will be the amount of material to be ground off the grind spacer on all of the new mandrel assemblies that are to be mounted on this particular machine to achieve a flush fit.

NOTE: Once the grind spacer has been adjusted, that set of mandrels need to stay with that machine. If the mandrels are moved to another machine the fit needs to be checked and new spacers ground, if necessary.