- Home

- About Us

- Machines

- Cups & Containers

- Support

- Contact Us

- Customer Portal

Service Bulletin: SB 184.3

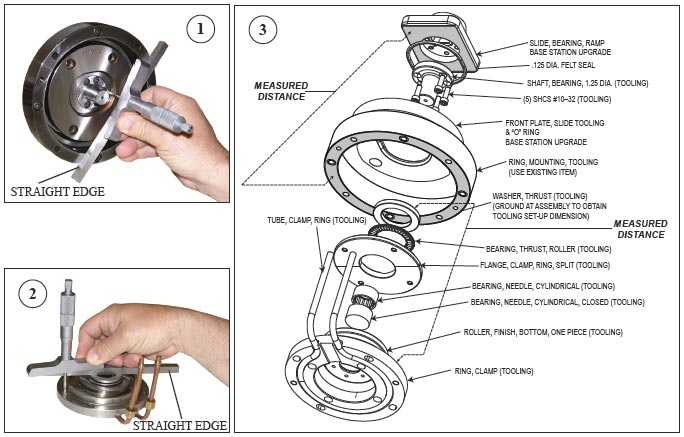

Subject: Improved Bottom Finish Tooling for Ramp Style Finish Stations — Extended Life of Tooling Roller Assemblies

Recommendations:

Click here to view SB 184.3 PDF

For Paper Machinery Corporation’s customers that have upgraded their PMC-1000 and PMC-1250 machines to a ramp style bottom finish station Paper Machinery Corporation is now offering a tooling upgrade.

A new design has been introduced and field tested labeled “Split Flange Thrust Style Roller Assembly”. This design incorporates a fitting spacer with a thrust bearing where the roller meets the bearing slide face shaft mounting flange. All cross loading of the roller during the sealing process is removed.

The new design in conjunction with once weekly maintenance of cleaning and grease has over doubled the life expectancy.

In addition to the tooling a one-time, per station upgrade is required to accommodate the new tooling design. Parts consists of a new Slide, Slide Front Plate, and Seal.

Station Upgrade Packages:

– PMC-1000 – #317-672

– PMC-1250 – #317-809

TOOLING INFORMATION:

If replacing existing “Split Flange” design a new Roller Assembly and Bearing Shaft are required. All other designs will require, in addition to above, a new clamp ring assembly.

INSTRUCTIONS:

To change from the design being used on your machine to the new design, the thrust washer needs to be ground for the correct fit.

EXAMPLE: (A) – (B) + .001″ = (C)

Grind (C) from the thrust washer

MAINTENANCE:

Once a week remove the bottom finish roller assembly from the station, clean the parts, inspect the parts (for damage or wear), and re-assemble. Prior to re-assembly, coat the flange with a film of grease and repack the needle bearing using Chevron Rykon EP 2 (HW-16629), Mobil Polyrex EP 2, or equivalent.

PURCHASING INFORMATION:

Information and pricing for the parts listed above cam be obtained by contacting any Paper Machinery Corporation’s Customer Service Department representative.