- Home

- About Us

- Machines

- Cups & Containers

- Support

- Contact Us

- Customer Portal

Service Bulletin: SB 215.1

Subject: Motor Brake

Recommendations:

Paper Machinery Corporation is pleased to offer a new Nexen Brake Assembly for the PMC-1002 & PMC-1001* machines. The Nexen Brake Assembly is a direct replacement for the (current) Wichita Brake Assembly, using 20 & 25HP motors.

The Nexen Brake offers a longer service life and simple installation. The installation process will require the use of a Special Nut Wrench (#220-813), available for purchase through PMC’s Parts Orders Department.

Refer to Service Instruction sheet #097.1 below for complete instructions on the PMC-1002 machine.

Refer to Service Instruction sheet #102.1 below for complete instruction on the PMC-1001 machine (equipped with a locknut).

* PMC-1001 motors are equipped with either a Straight Shaft (which requires set screws) or a LockNut that secures the motor brake. The Special Nut Wrench only applies to PMC-1001 motors equipped with a LockNut (and all PMC-1002 motors).

For PMC-1001 motors equipped with a Straight Shaft, refer to Service Instruction sheet #100.1 below for complete installation instructions.

INSTALLING THE NEXEN BRAKE ASSEMBLY

INSTALLING THE NEXEN BRAKE ASSEMBLY

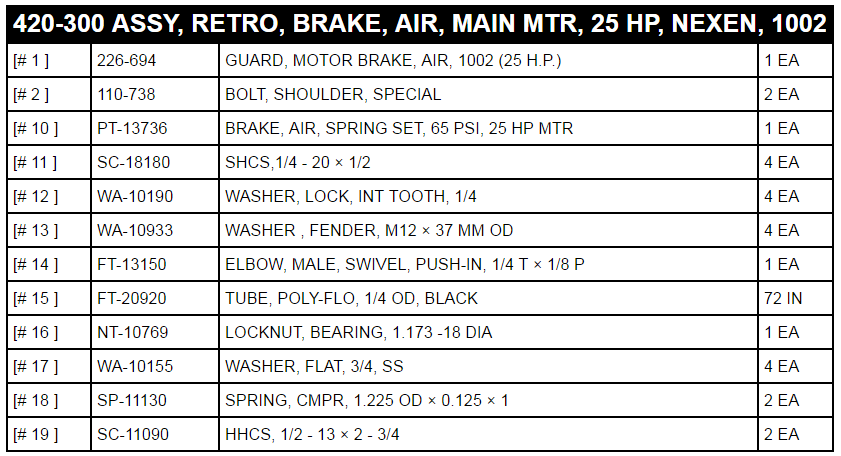

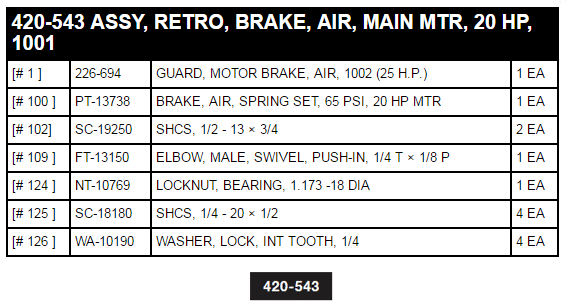

Refer to Drawing #420-300 and proceed as follows.

INSTALLING THE NEXEN BRAKE ASSEMBLY

INSTALLING THE NEXEN BRAKE ASSEMBLY

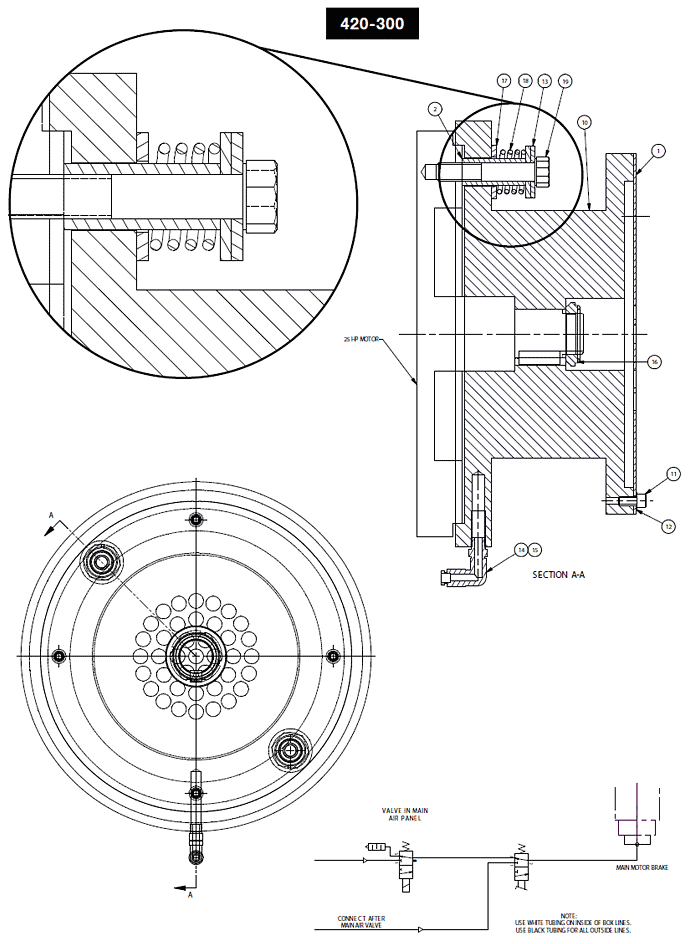

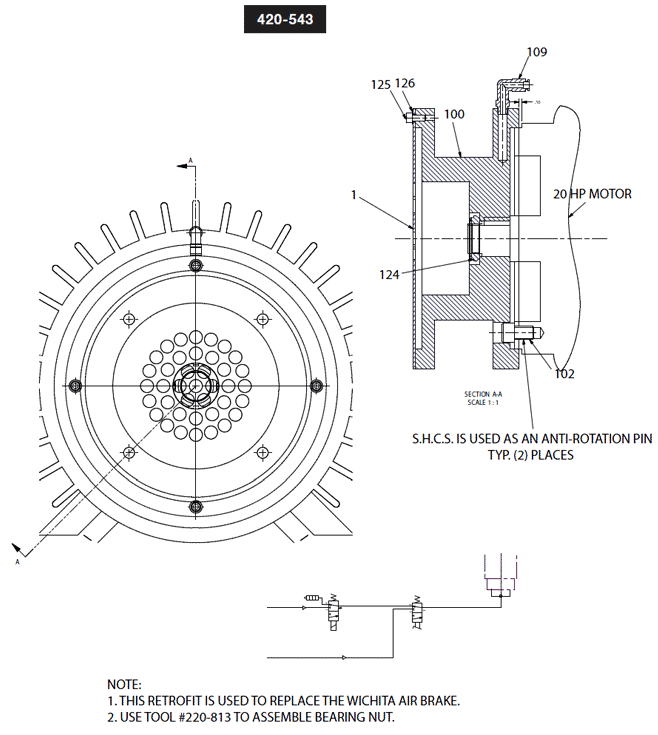

Refer to Drawing #420-543 and proceed as follows.

INSTALLING THE NEXEN BRAKE ASSEMBLY

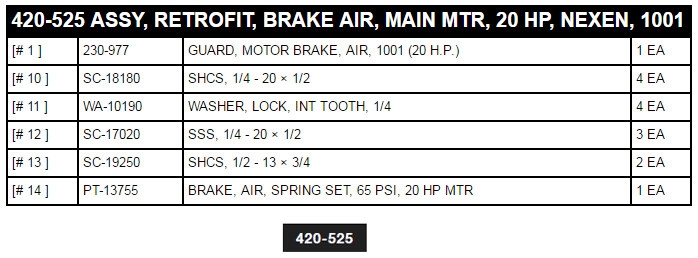

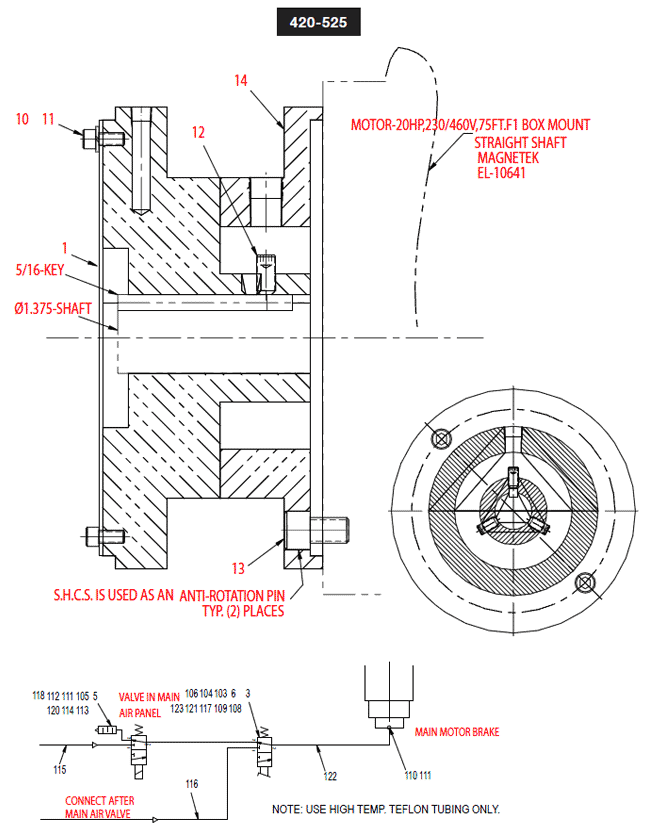

Refer to Drawing #420-525 and proceed as follows.

CONTACT: Parts orders and customer communication can be made using telephone, FAX, or e-mail. Contact can still be made using the main telephone switchboard at 414-354-8050 or FAX number 414-354-8614. Sending a FAX directly to the Service Department, at 414-354-1710, will convey a faster response. If using e-mail and no response is made within 3 working days, please contact via phone or FAX.

Parts orders can be directed to Holly Warner or Vicky Alcaraz using telephone, FAX, or e-mail. Please make sure to carbon copy (CC) both Holly Warner and Vicky Alcaraz in all e-mails containing parts orders. Service issues can be directed to Steve Evans or Mike Ferguson and electrical issues to Larry Spencer.